truss bolts

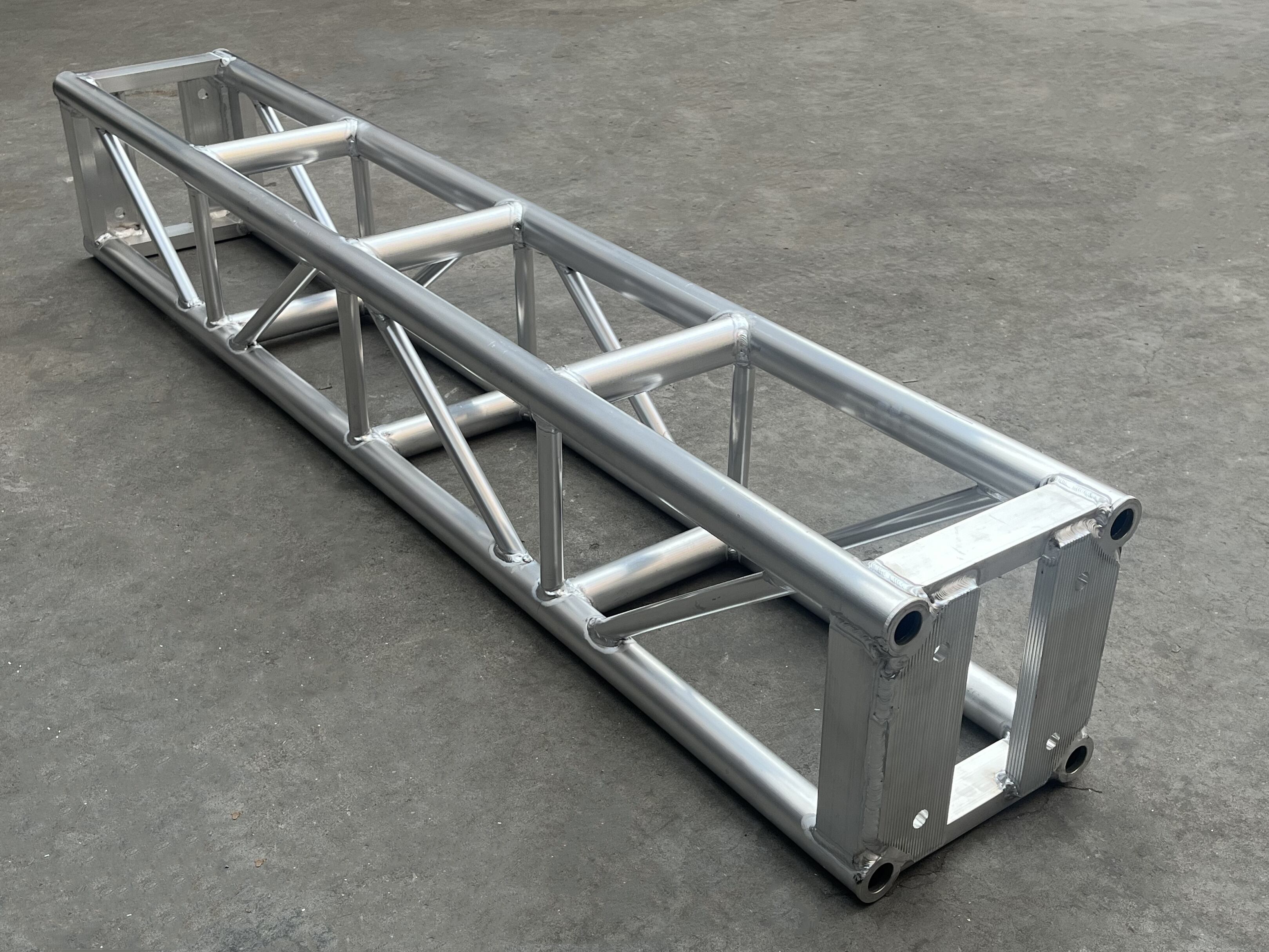

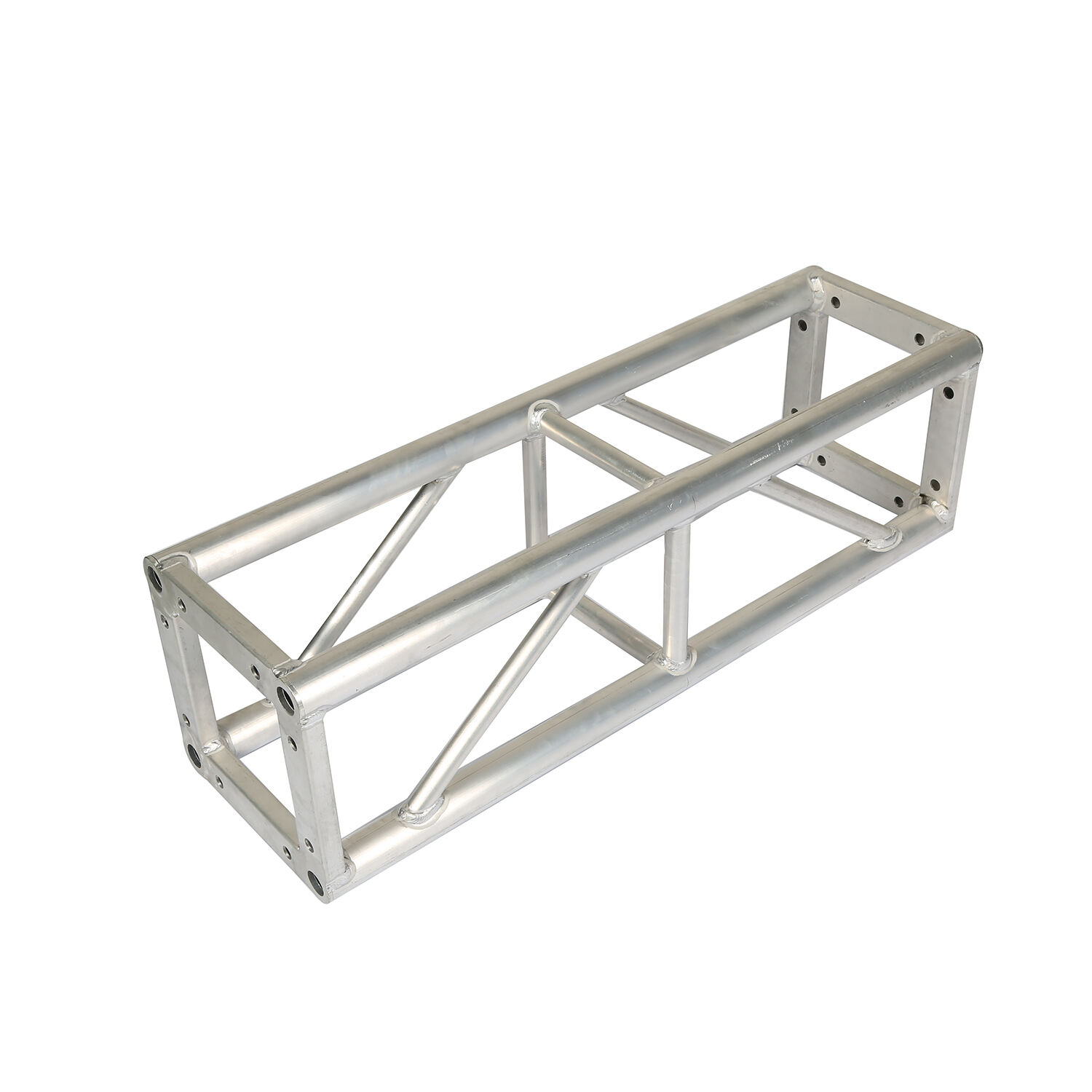

Truss bolts are essential fastening components specifically engineered for structural applications, particularly in construction and industrial settings. These specialized fasteners are designed to provide superior strength and reliability in connecting truss members and supporting heavy loads. Made from high-grade steel and featuring precision threading, truss bolts are characterized by their large, low-profile heads and robust construction that ensures even pressure distribution. The distinctive design includes a wide bearing surface under the head, which helps prevent damage to the connected materials while maintaining structural integrity. These bolts are available in various sizes and lengths to accommodate different structural requirements and load-bearing capacities. They are particularly valuable in roof truss assemblies, bridge construction, and industrial framework where stability and durability are paramount. The manufacturing process involves careful material selection and rigorous quality control to ensure each bolt meets strict engineering standards. Truss bolts typically feature corrosion-resistant coatings or treatments to enhance their longevity and performance in various environmental conditions. Their application extends beyond traditional construction, finding use in heavy machinery assembly, theatrical rigging, and specialized industrial equipment where secure, reliable connections are crucial.