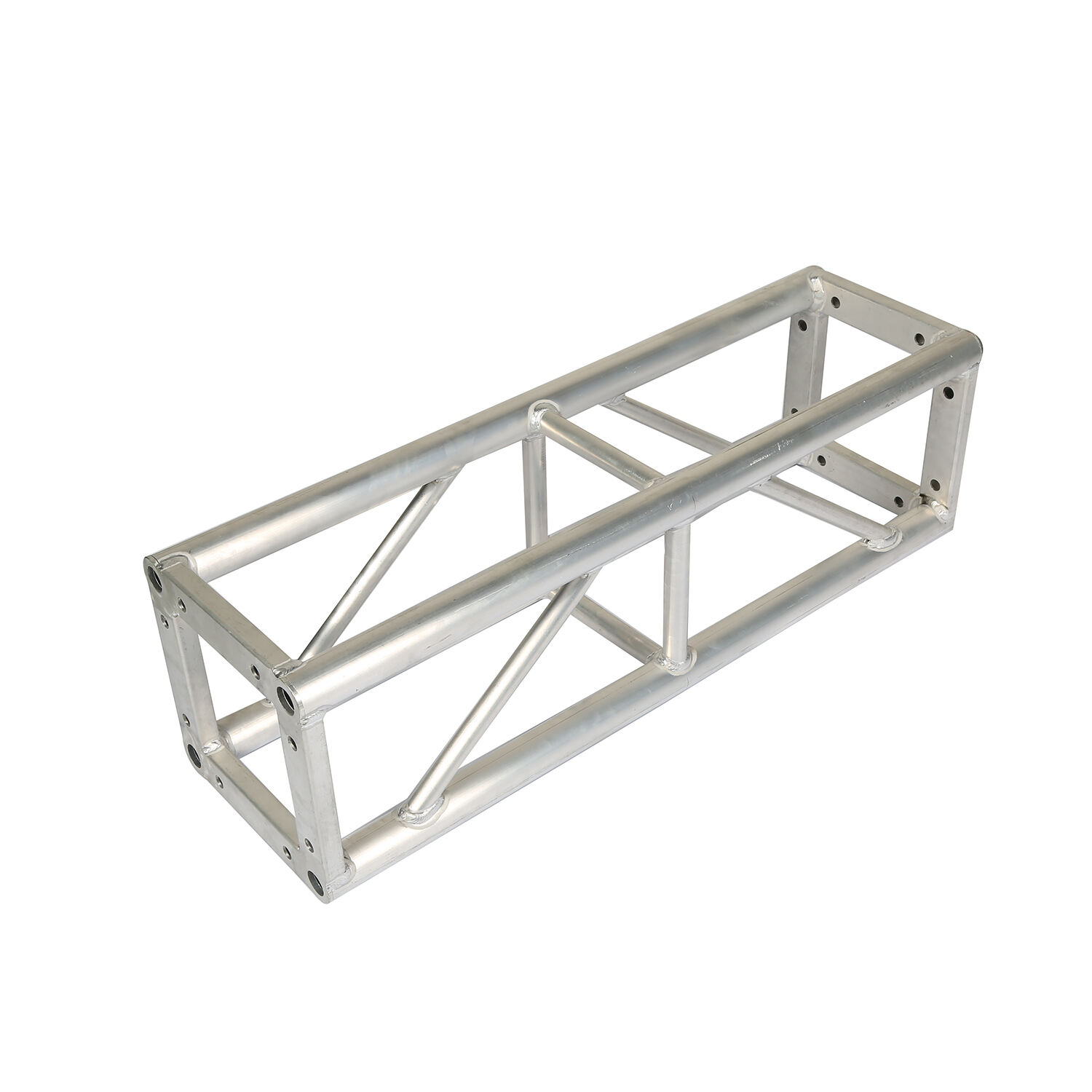

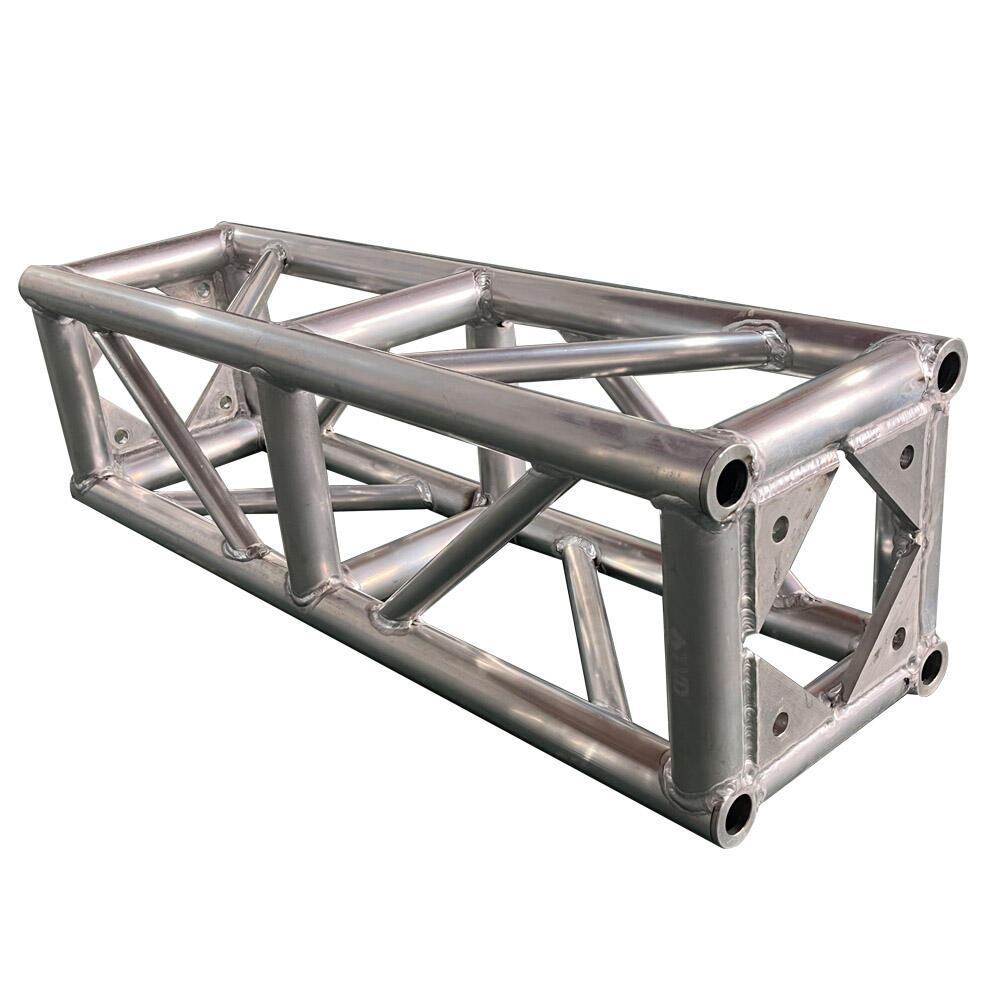

bolt truss

A bolt truss is an innovative structural system that combines the strength of traditional truss designs with modern bolt connection technology. This engineering marvel consists of interconnected metal members, typically steel or aluminum, joined together using high-strength bolts to create a rigid framework capable of supporting significant loads. The system's primary function is to distribute weight and forces across large spans efficiently, making it ideal for commercial, industrial, and residential construction projects. The bolt truss utilizes precision-engineered connections that allow for quick assembly and disassembly, while maintaining structural integrity. These connections feature specially designed bolt patterns that ensure optimal force distribution and minimal stress concentration. The system incorporates both primary and secondary members, working in harmony to provide superior load-bearing capacity while minimizing material usage. Modern bolt trusses often feature galvanized or powder-coated finishes for enhanced durability and corrosion resistance, extending their service life significantly. The design flexibility of bolt trusses allows for various configurations to accommodate different architectural requirements and load conditions, making them versatile solutions for diverse construction challenges.