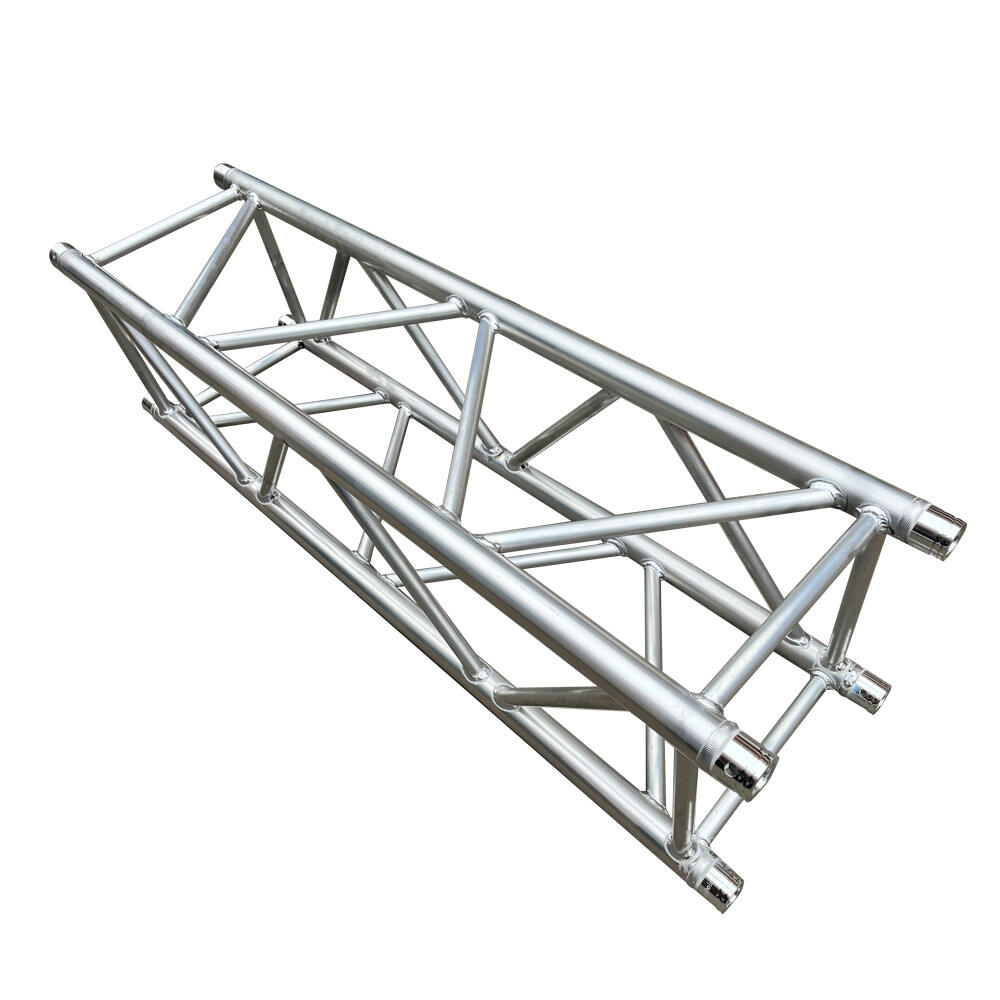

concert spigot truss

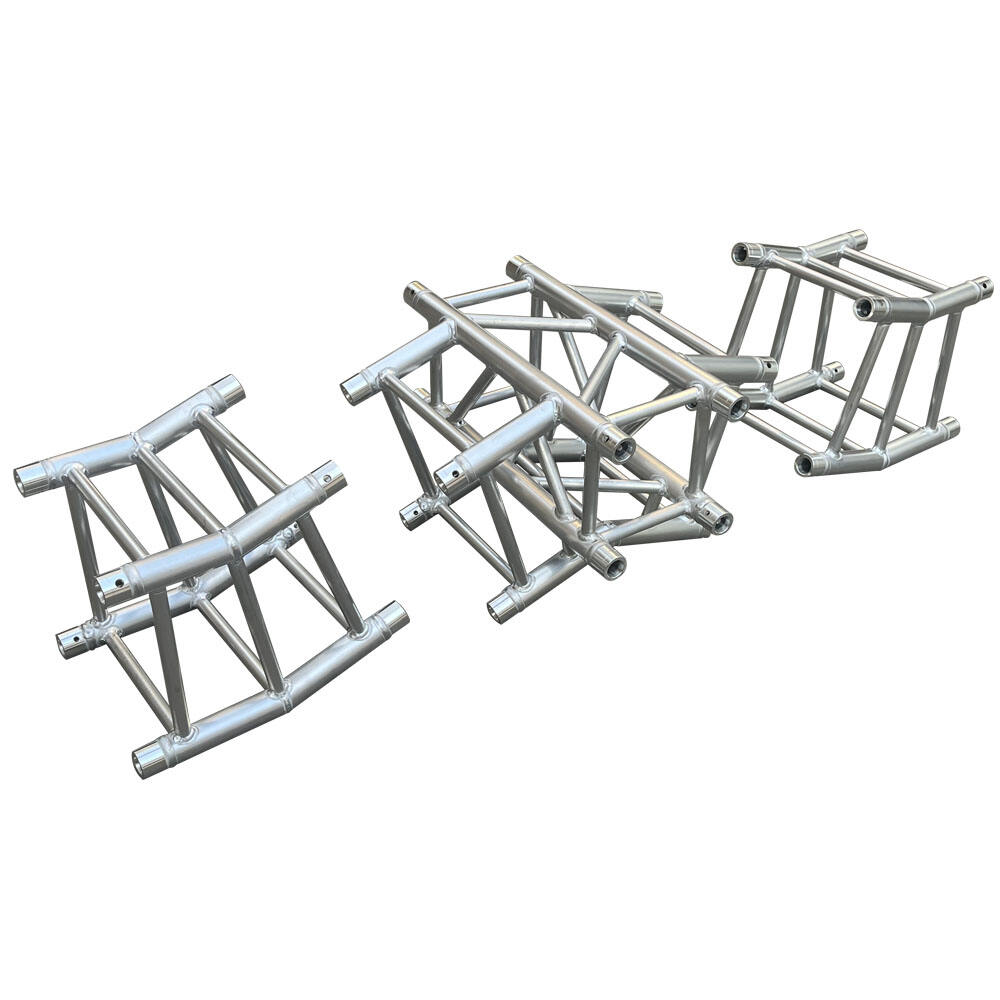

The concert spigot truss represents a cornerstone in modern event production and structural engineering. This sophisticated aluminum framework system utilizes precision-engineered connecting mechanisms, known as spigots, to create robust and versatile support structures for entertainment venues and outdoor events. The system comprises high-grade aluminum alloy sections connected through male and female spigot joints, ensuring quick assembly and exceptional structural integrity. These trusses are specifically designed to support substantial loads while maintaining optimal weight distribution, making them ideal for suspending lighting equipment, audio systems, and video displays. The innovative spigot connection system allows for rapid deployment and dismantling, significantly reducing setup time while maintaining maximum safety standards. Each component undergoes rigorous quality control and testing to meet international safety regulations and load-bearing requirements. The concert spigot truss system features standardized components that can be configured in various arrangements, offering flexibility in design and application. This adaptability makes it particularly valuable for touring productions, festival setups, and permanent installations in theaters and concert venues.