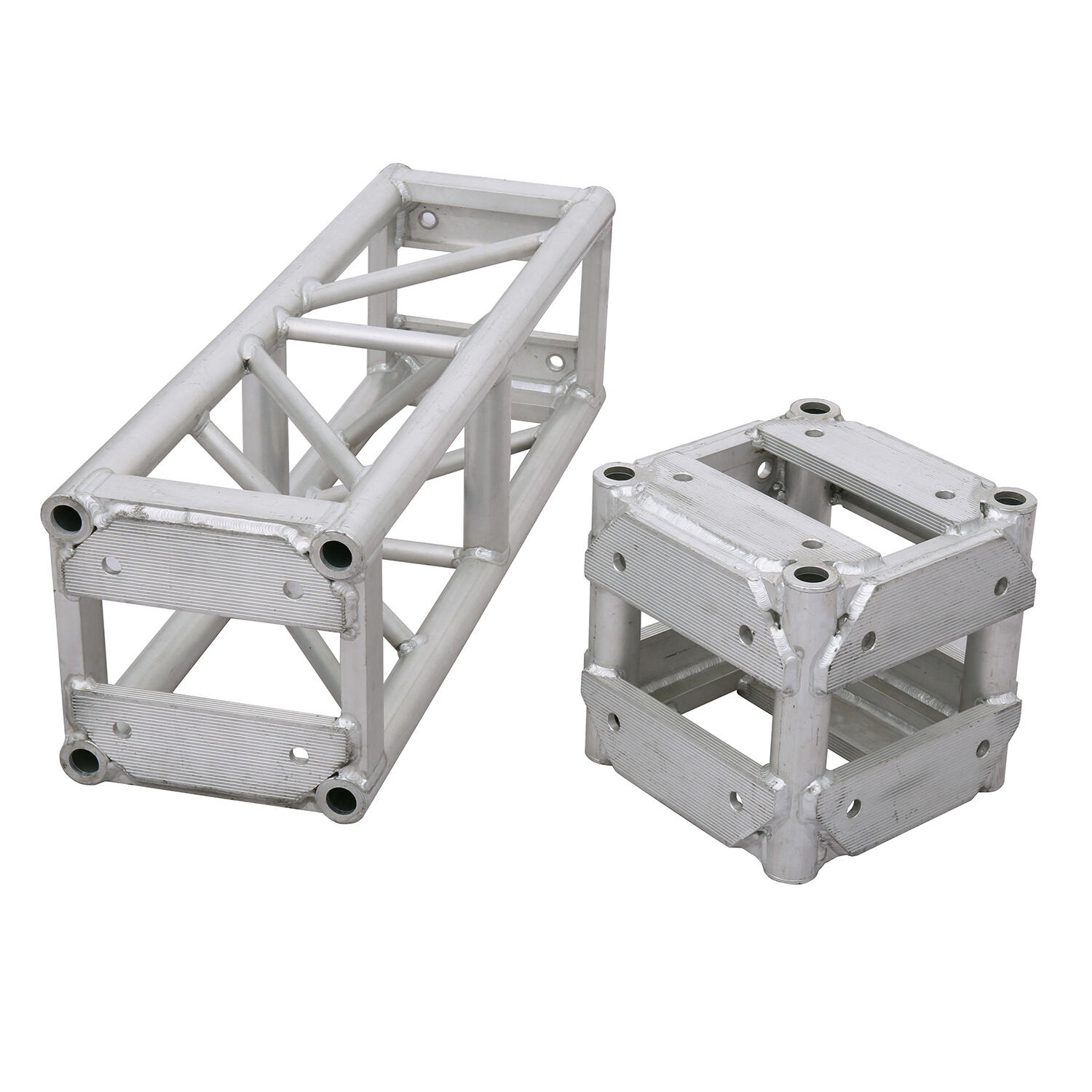

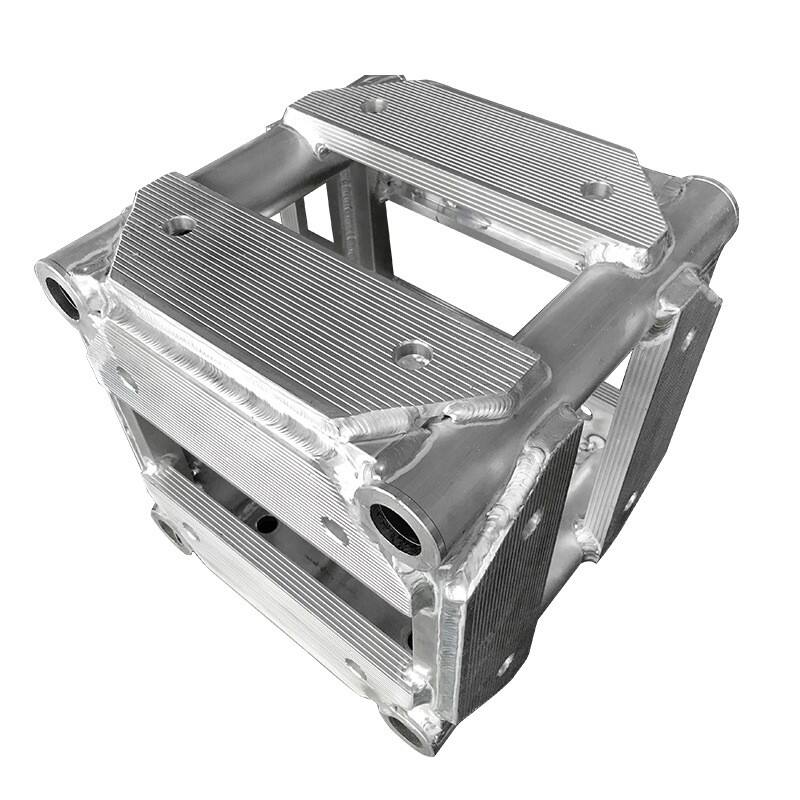

aluminum box truss

The aluminum box truss represents a cornerstone of modern event infrastructure and structural engineering. This versatile system consists of interconnected aluminum segments forming a robust three-dimensional framework, specifically engineered to provide exceptional strength while maintaining a lightweight profile. The box truss design incorporates four main chords connected by diagonal and horizontal bracing members, creating a geometric pattern that maximizes load distribution and structural integrity. These systems are manufactured using high-grade aluminum alloys, offering an optimal balance of durability and portability. The standard configurations typically range from 290mm to 400mm in cross-section, though custom sizes are available to meet specific requirements. The modular nature of aluminum box trusses allows for quick assembly and disassembly, featuring innovative connecting mechanisms that ensure secure joints while facilitating rapid deployment. These structures excel in supporting various loads, from lighting and audio equipment to LED screens and decorative elements, making them indispensable in entertainment venues, exhibitions, and architectural applications. The engineering behind aluminum box trusses incorporates precise calculations for load-bearing capacity, spanning capabilities, and deflection limits, ensuring safety and reliability in diverse applications.